Our graphene-based solutions can enhance these key desired performance characteristics while also improving the overall cost/performance balance. Additionally, used tires could become a carbon source for the Flash Joule Heating process thus improving overall sustainability for this industry.

Tire & Rubber Market Dynamics

The key requirements for new materials to be used in tire & rubber applications are durability, sustainability, and a compelling value proposition.

- Diverse applications: Tires, Hoses, Belts, Conveyors, Seals, Adhesives, Gaskets, Footwear, Protective covers, Floor Mats, etc.

- There were approximately 1.47 billion tires produced in 2023

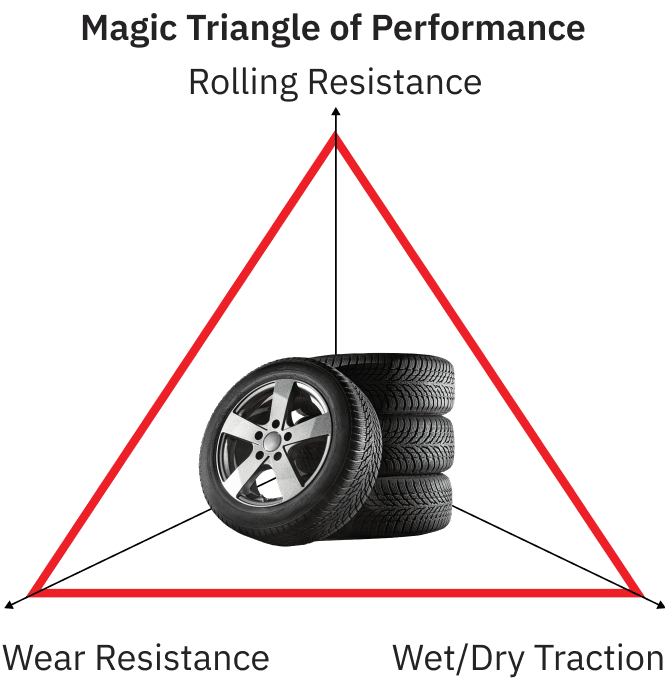

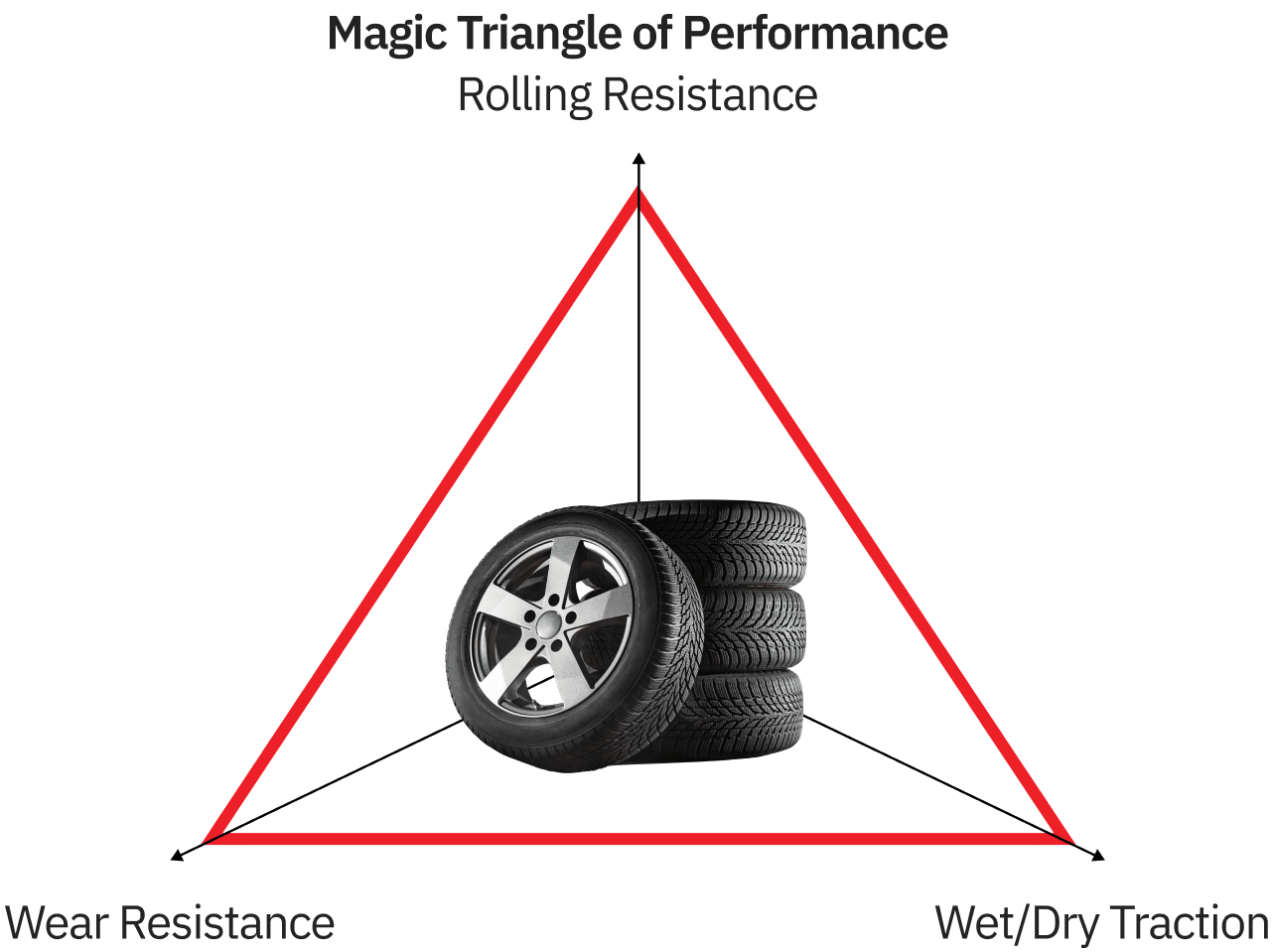

The three corners of the magic triangle represent:

- Wear Resistance: The tire’s ability to resist wear and maintain its tread life.

- Fuel Efficiency: The tire’s contribution to reducing rolling resistance and improving vehicle fuel economy.

- Traction: The tire’s grip and handling performance on various road conditions.

The magic triangle highlights the trade-offs involved in tire design and compound development.

Tire Manufacturers Challenges

- Average car loses ~2.4 kg (5.3 lbs) of rubber/year

- Globally: tire wear particles contribute 6M tons/year of micro-plastics¹ pollution into the environment.

- Trend: EVs weigh 22-35% more than ICE counterparts, making tire wear worse.

- Tire Manufacturers aim to find the best trade-off within the magic triangle to perform well across all 3 areas.

1 ADAC e.V. Report entitled “Tyre Abrasion: Wear and Burden on the Environment”, Dec. 2021

Changing the Magic Triangle Paradigm and Creating Strong Circular Economics for Tires

Key Benefits of our graphene-based solutions

- Reduce abrasion losses by 20 to 40%; Enables reduction in airborne micro-contaminants

- Reduce rolling resistance and concurrently improve fuel economy by ~10% without losses in traction

- Improve modulus, tear strength, and heat dissipation

- No negative impact to wet/dry traction or other mechanical performance characteristics

- We can deliver these benefits using graphene derived from waste tire carbon