HYCOTE Graphene Anti-Corrosion Primer

Utilizing Graphene Nanoplatelets to Deliver Market-Leading Performance in Automotive Anti-Corrosion Respray Primers

Increased corrosion resistance by 300%

Zinc Free – no Zinc Phosphate or other heavy metals

Excellent Adhesion and Flexibility

The Challenge

James Briggs Ltd was founded in the North of England almost two centuries ago. Since 1830 it has combined extensive technical expertise with industry-leading design to provide innovative products that bring added value to its customers.

As part of its innovation program to create next-generation coatings, James Briggs approached Universal Matter with the idea to incorporate graphene nanoplatelets into its standard aerosol primer.

The scope of the project to add Graphene nanoplatelets was outlined by James Briggs as follows:

- Significantly increase the anti-corrosion performance of its standard primer

- Maintain manufacturing and application processability of the aerosol coating

- Ensure no negative impact on physical properties as a result of the addition

- Balance value-adding performance benefit with added costs to ensure the commercial viability of the new primer

Success Through Development Partnership

The development collaboration between the technical teams at Universal Matter and James Briggs led to the development of HYCOTE GRAPHENE ANTI-CORROSION PRIMER

- Exceptional Anti-Corrosion Performance >1750 Hours (ASTM G-85 Annex 5-Prohesion)

- Zinc Free – Reduced environmental hazard compared to conventional anti-corrosion primers

- Optimized formulation to ensure maximum value-adding performance benefits while limiting the impact on product costs

- Outstanding Barrier performance significantly extending the life of the coating

- Extremely fast drying

- Excellent adhesion to both metallic and plastic substrates

- Outstanding Flexibility – No cracking on conical mandrel test (ASTM D-522)

Following the completion of the formulation development work, Universal Matter continued to support James Briggs’ development with a forerunner to our Innovation Accelerator development program by running the coated panels in UM’s prohesion salt spray cabinet – the result was OUTSTANDING.

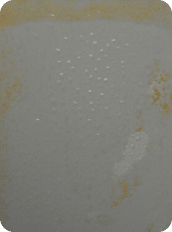

168 hours

168 hours

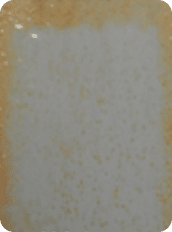

336 hours

336 hours

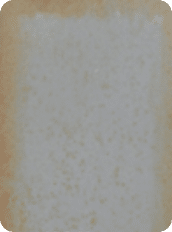

432 hours

432 hours

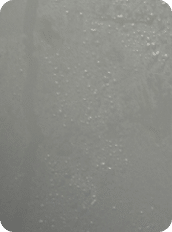

696 hours

696 hours

1000 hours

1000 hours

1750 hours

1750 hours

168 hours

168 hours

336 hours

336 hours

432 hours

432 hours

696 hours

696 hours

1000 hours

1000 hours

1750 hours

1750 hours