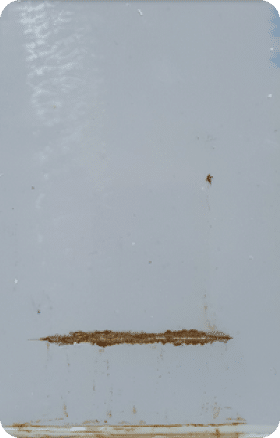

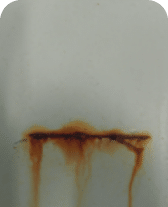

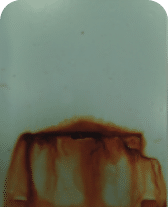

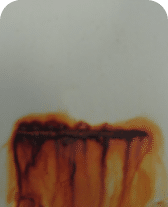

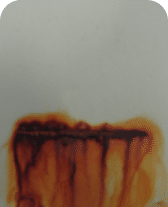

Prevent corrosion the easy way

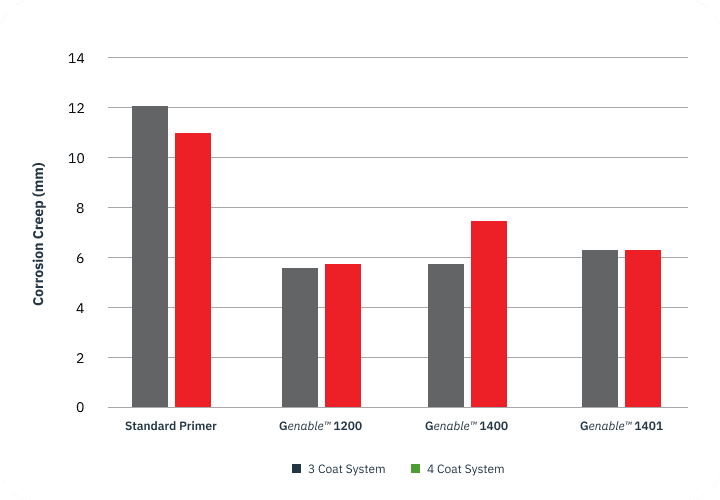

When coating steel, priming is key to preventing the formation of rust. The GenableTM anti-corrosion primer range enhanced with graphene nanoplatelet dispersions offers a new innovative approach to combatting corrosion.

Our graphene-based corrosion protection primers can demonstrate the ease of application and transformational performance benefits of graphene-enhanced coatings.

CHECKOUT OUR NEW CORROSION TOOLBOX

Epoxy Primer

Epoxy Primer