Paints and Coatings

Universal Matter's graphene nanoplatelet and graphitized carbon based Genable™ dispersions can be easily incorporated into high performance coatings, such as epoxy and polyurethane industrial paints.

The addition has the potential to enhance a range of properties from barrier, chemical resistance and corrosion protection to increased conductivity and mechanical property improvements.

How do our Graphene Nanoplatelets and Graphitized Carbons Work?

Universal Matter is proud to offer a range of graphene nanoplatelets and graphitized carbon dispersions that are safe to handle and easy to incorporate into new and existing coating systems. The addition of these Genable™ dispersions offer coatings innovations a range of exciting performance enhancement possibilities.

UM is uniquely positioned to be able to offer a broad range of graphene morphologies, levels of functionality, and particle sizes and structures, which enable us to be able to optimize our product offering to best suit the end application.

With the correct optimized product and incorporation levels, UM’s Genable™ dispersions have the potential to significantly enhance an array of properties, including mechanical, barrier, thermal, and electrical conductivity performance in new and existing paints and coatings systems.

Performance Additives for Better Paints and Coatings

By incorporating a Genable™ Dispersions, Universal Matter is enabling coatings formulators to easily realize the performance benefits of graphene advanced related materials in their innovations.

Anti Corrosion

Adding a graphene dispersion as a complimentary anti-corrosion additive can extend the life of industrial coatings and other assets.

Excellent results are possible, either as a stand-alone corrosion inhibitor or as a result of the synergistic performance of the graphene in combination with existing systems.

Barrier Coatings

Industrial barrier paints and coatings are specialized protective layers designed to shield surfaces from water, gases, and other potentially damaging substances. These coatings play a crucial role in various industries by enhancing the durability and performance of materials and structures.

Universal Matter’s Genable™ dispersions have demonstrated outstanding performance for enhancing barrier properties in polymers and composites, offering significant improvements in gas and moisture resistance. Here's an introduction to their outstanding barrier performance:

Structure and Properties

Genable™ dispersions improve barrier performance through several mechanisms:

- Increased tortuosity: The platelet structure distributed through the coating film creates a tortuous path for gas and moisture molecules, significantly extending diffusion pathways.

- Impermeability: Graphene's molecular structure is inherently impermeable to most gases and liquids.

- High aspect ratio: The large surface area and thin profile of graphene nanoplatelets mean they are highly effective barrier pigments at extremely low loading levels.

Benefits:

- Extended Asset Lifespan: enabling longer last higher performing coatings

- Environmental Protection: preventing leaks and contamination, barrier coatings help safeguard the environment.

- Asset Lifetime Cost Savings: these coatings reduce long-term maintenance and replacement expenses.

- Improved Safety – maintaining structural integrity, barrier coatings enhance workplace safety.

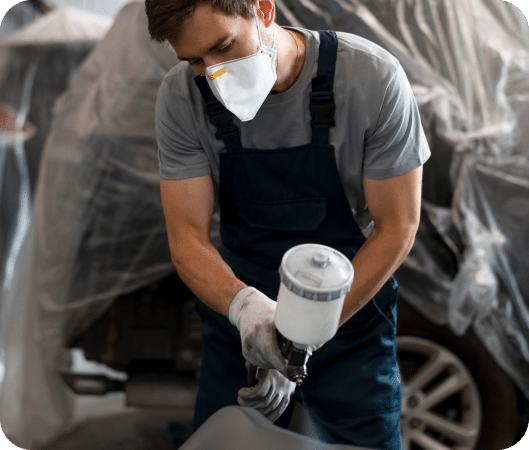

Car Care

The addition of graphene into car care systems has significantly enhanced the properties of waxes, polishes and detailing products.

The large surface area, barrier performance, low density, mechanical strength and morphology of Universal Matter’s graphene nanoplatelets, make them ideal materials for the production of superior car care products.

Chemical Resistance

Incorporating graphene into a high performance coating can increase its resistance to harsh chemicals and offer greater surface protection.

The chemical resistance benefits of graphene are clear from our comprehensive data package, showing less blistering, an improvement in gloss retention, and greater shore hardness.

Conductivity

Universal Matter’s graphene nanoplatelets have a two-dimensional form that can also be employed to develop thermally conductive materials.

Thermal management materials enhanced with graphene help to dissipate heat build-up from components and facilitate rapid heat transfer.

Mechanical Coatings

The incorporation of Universal Matter’s graphene and related advanced materials into resin-based coatings has the potential to significantly enhance the mechanical properties of the finished paints.

Through the interactions with the resin, the Genable™ dispersions enable increased tensile properties, toughness, abrasion resistance and scratch resistance.

Why Choose Graphene as a Functional Ingredient?

As a flexible and innovative solution, graphene enables the development of better performing paints and coatings that can last longer and are kinder to the environment.

Graphene offers product life cycle advantages and reduces the environmental impact of paints and coatings, as an eco-friendly, metal-free alternative to traditional additives:

- Stronger, longer lasting coatings enable extended asset service life and reduced maintenance

- Reduction or replacement for heavy metal additives and toxins such as chromates also PFAS free

- Enables fewer and thinner coats

- Environmentally friendly dispersion options, such as water based and VOC free systems

Working with Universal Matter to Incorporate Graphene Technology

UM has developed an industry-leading position in the graphene industry.

Universal Matter's expertise lies in the consistent supply of high quality, repeatable graphene dispersions that are stable, easy to formulate and safe to incorporate into a range of applications, supported with in-depth test data.

Offering a decade of experience, the latest lab technology and the stringent environmental controls required to handle graphene powder, UM’s expert team of chemists can work with you to incorporate graphene additives so you can offer customers next generation industrial coatings.

As a growing global manufacturer of graphene dispersions for the paints and coatings sector, UM is a proud member of following:

To speak to a member of our sales team and find out how you can get ahead of the competition using graphene nanoplatelets. Call us on +44 (0)1642 438214 or drop us a message