Decarbonization

The United Nation Sustainability and Development Goals

Universal Matter’s products lend themselves to enhancing the materials they are added into. This is through the remarkable properties that our distinct graphene-based formulations and dispersions are able to deliver using our dispersed materials product offerings. The performance gain is not just immediate – there can be a positive impact on life cycle costs for products in the concrete, asphalt, and tire/rubber markets . Extended product life cycles manifest themselves principally in graphene enhanced materials that last longer – evidenced, for example, with our Genable™ Decarbonizer for concrete and Genable™ Pavement for asphalt.

The potential benefit for asset owners arising from a reduced maintenance cost burden and increased asset utilization is significant as a result. We, therefore, see that graphene has an important and exciting role to play in the opportunities we are pursuing for environmental and sustainability benefits.

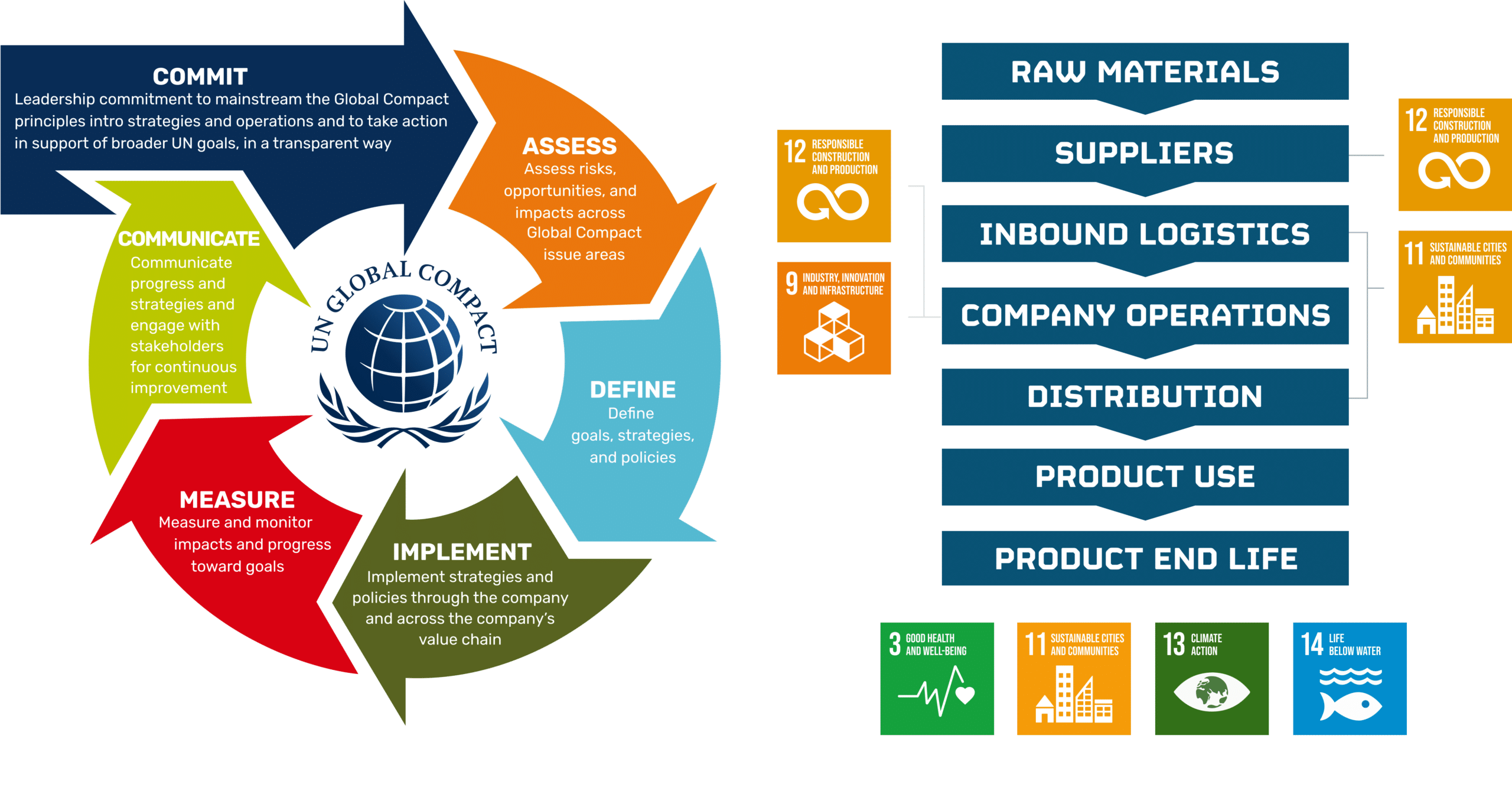

Outside of our product utility, we take our obligations seriously in the way we manage our business and our relationships with all our stakeholders.

Environmental Advantage

Graphene has the potential to provide a significant environmental advantage to the human race by strengthening, and therefore reducing the volume used, of many of the raw materials we use every day: concrete, asphalt, plastics, rubber and paint, to name just a few. For applications where the volume cannot be reduced, graphene promises to significantly improve the life cycle of products. For example, graphene in asphalt has been shown to improve cracking resistance, improve rutting resistance, increase the temperature performance grade by 2 “bumps”, with all of this resulting in longer pavement life. Universal Matter will deliver all of these advantages with less graphene thanks to its superior purity and dispersibility. The uniform distribution of graphene through the material it is aiming to enhance is key to delivering the superior properties and durability.

The combination of reducing the use of primary materials like concrete through the use of graphene and making the graphene from renewable or recycled feedstocks, hold enormous potential to both reduce the human footprint and curtail global warming through the reduction of GHG emissions.

Building the Road to the Circular Economy

Call To Action

Global tire production is ~23M mt/year in 2024

Global tire industry responsible for >20M mt/year of CO2 emissions

– ~2.35M mt/year of CO2 emissions from tire production

– Additionally, incineration of end-of-life tires (EOL) adds another ~18M mt/year>1B tires become waste each year

– This equates to ~26M mt of waste

– ~89% of this waste is collected

– ~70% of this waste is processed for energy recovery, material recovery,

or civil engineering use

– ~8M mt/year (~30%) of this waste ends up in landfills

Waste rubber tire Graphene to enable upcycling of waste rubber tires and plastic

- Transform recycling into a value creation process from polyhedral graphene via our Flash Joule Heating (FJH) process.

- Our patented FJH technology efficiently produces high-quality graphene at low costs from diverse carbon sources, starting with discarded tires (post pyrolysis process), heralding a shift from waste to valuable polyhedral graphene.

- Introduce polyhedral graphene into carbon-intensive products such as rubber, composites, asphalt, etc., establishing a self-sustaining circular carbon economy.

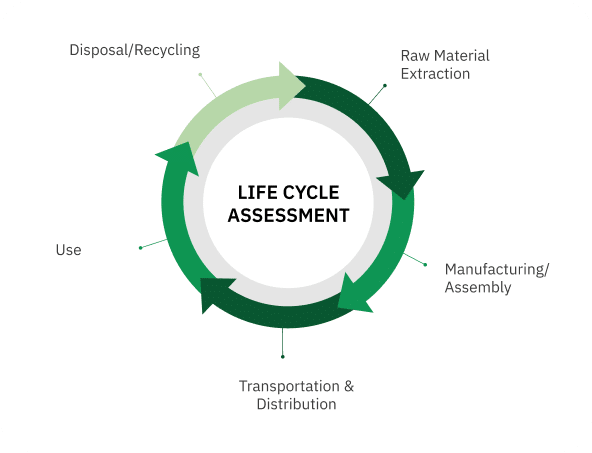

Life Cycle Assessment (LCA)

The primary goal of LCA is to quantify the environmental effects of material inputs and outputs, such as energy use and emissions, to help make environmentally beneficial decisions.

LCA - Life Cycle Assessment

- Assessment of the environmental impacts associated with the life cycle (or a subset of life cycle stages) of a product or process, in accordance with ISO 14040/44.

- Independent third-party completed preliminary LCA for UMI during early-stage process and product development in 2021. The LCA will be updated in 2025 with inclusion of the fully operational manufacturing plant and commercial products in key markets.

EPD - Environmental Product Declaration

- Summary of the output of the LCA in a public facing document, in accordance with ISO 1402.

- We have commenced the process to complete EPD's for some of our leading products in the markets we serve. We expect initial EPD's to be complete in 1Q 2025.

Genable Dispersions enable eco-friendly innovation

Material scientists are becoming increasingly conscious of the safety and environmental impact of their new innovation as consumers demand safer and more sustainable finished products. Growing pressure to comply with increasingly stringent health and safety legislation and demonstrate a reduced environmental impact is pushing manufacturers to innovate with raw materials that support these demands.

In addition to helping industry meet their environment product goals through extension of asset life and improvements in performances, UM are proud to supply many of its Genable™ dispersions in environmentally friendly media. These products reflect UM’s own sustainability commitments to continuous improvement to align with the principles of the UN Sustainability Development Goals.

To find out more about Universal Matter’s responsibilities and our commitment to our employees, our local communities and the environment around us, please get in touch through our contact page.

Our expertise

Our range of environmentally friendly dispersions of graphene and related advanced materials, enable industry to innovate in water-based application as well as reducing VOCs to move toward solvent free systems.